You don’t need to be an expert to get great results with a small scale rice milling machine. Many people now choose to process rice at home or in small shops. This machine makes it easy to turn paddy into fresh, high-quality rice. You save money and get more control over your food. With a small scale rice milling machine, you can enjoy the taste and satisfaction of milling your own rice.

What Is a Small Scale Rice Milling Machine

A small scale rice milling machine lets you turn raw paddy into clean, polished rice right at home or in your shop. You don’t need a huge factory or a team of experts. These machines are compact, easy to use, and perfect for small-scale rice processing. They help you get fresh rice with less effort and cost.

Key Components

Huller

The huller is where the magic starts. You pour in your paddy, and the huller removes the tough outer husk. It uses friction and pressure to separate the husk from the rice grain. This step is important because it protects the rest of the rice milling process and helps you get more whole grains.

Whitening Machine

Next comes the whitening machine. Here, the brown rice from the huller goes through a polishing process. The machine rubs off the bran layer, making the rice white and shiny. You can adjust the pressure and speed to get the level of rice polishing you want. If you want extra shine, some machines even let you add a mist of water for a final touch.

Separator

The separator sorts out any grains that didn’t get milled properly. It makes sure only fully polished rice moves forward. This step helps you avoid mixing unprocessed grains with your finished product. You get a better yield and more consistent rice quality.

Tip: Regularly check and clean each part of your rice milling machine. This keeps your rice polishing and milling process smooth and prevents jams.

How It Works

Let’s break down the milling process step by step:

Pre-cleaning: Clean your paddy to remove stones, weed, and dirt. This protects your rice milling machines and improves the final rice quality.

Dehusking: The huller removes the husk, giving you brown rice.

Paddy Separation: The separator pulls out any grains that still have husks.

Whitening/Polishing: The whitening machine removes the bran and polishes the rice. You can control the polishing process for the look and feel you want.

Grading: The machine sorts the rice into whole and broken grains.

Mixing and Final Polishing: Some machines mix different grades and add a mist for extra shine.

Weighing: You weigh and pack your finished rice.

Benefits for Beginners

You don’t need special training to use a small scale rice milling machine. These machines are simple, with clear controls and easy maintenance. You save space, money, and time. You also get to enjoy fresh rice whenever you want. Unlike large rice milling machines, you don’t need a big team or advanced skills. You can handle the whole milling and polishing process yourself.

Here’s a quick comparison to show how small scale rice milling machines stack up against industrial models:

| Aspect | Small Scale Rice Milling Machine | Large Scale Rice Milling Machine |

|-------------------------|-------------------------------------------|-----------------------------------------|

| Capacity | Small batches for home or local use | Thousands of kilos per hour |

| Design | Compact, basic, easy to move | Large, advanced, needs more space |

| Power Consumption | Low | High |

| Cost | Affordable | Expensive |

| Technology | Manual or semi-automatic | Fully automatic, uses AI and IoT |

| Labor | Easy for beginners | Needs skilled workers |

| Space | Small area needed | Large area required |

| Market Focus | Local and small businesses | Commercial and export |

You get all the essentials for rice processing without the hassle. With regular care, your rice milling machine will keep producing high-quality rice and smooth polishing results for years.

Beginner’s Guide: Choosing a Small Scale Rice Milling Machine

Choosing the right small scale rice milling machine can feel overwhelming, but you can make it simple by focusing on your needs and the key features that matter most. This beginner’s guide will walk you through the main types, what features to look for, and where you can buy a reliable rice milling machine.

Types of Rice Milling Machines

You will find a few main types of rice milling machines on the market. Some machines are manual, which means you turn a handle or use a foot pedal. These work well if you only need to process small amounts of rice and want to save on electricity. Electric machines are more common for beginners. They use a motor to do the hard work, so you just load the rice and press a button. Some models combine hulling, whitening, and separating in one unit, while others let you swap out parts for each step.

Tip: If you want to save time and effort, choose an electric model with all-in-one functions.

Features to Consider

When you compare rice milling machines, focus on these key features. They will help you get the best results and make your work easier.

Capacity

Think about how much rice you want to process at one time. Some machines handle just a few kilos per batch, while others can do more. If you plan to mill rice for your family or a small shop, a lower capacity machine will work fine. For bigger needs, look for a model with a larger hopper and faster output.

Ease of Use

You want a machine that is simple to operate. Look for clear controls, easy-to-read labels, and a design that lets you load and unload rice without hassle. Some machines even have digital displays or preset programs. These features make the process smoother, especially if you are new to rice milling.

Maintenance

Regular maintenance keeps your rice milling machine running well. Choose a model with parts that are easy to remove and clean. Some machines come with cleaning tools or guides. Good maintenance features save you time and help you avoid breakdowns.

Rice Quality

The quality of your finished rice depends on the machine’s design and settings. Look for machines that let you adjust pressure and speed. This helps you get the right level of polishing and fewer broken grains. Machines with good separators and polishers will give you better rice quality every time.

Note: Key features like capacity, ease of use, maintenance, and rice quality make a big difference in your daily milling experience.

Key Features Table

| Key Features | Why It Matters |

|-------------------|-----------------------------------------|

| Capacity | Matches your daily or weekly needs |

| Ease of Use | Makes operation simple for beginners |

| Maintenance | Keeps your machine in top shape |

| Rice Quality | Ensures tasty, polished rice |

Where to Buy

You can buy rice milling machines from local dealers, online marketplaces, or specialized suppliers. Websites like chinaricemill.com offer a wide range of models and often provide detailed manuals. Always read the manual before you start. It helps you understand the key features and safety steps. Compare prices, check reviews, and ask about after-sales support. A good supplier will answer your questions and help you pick the best machine for your needs.

Here’s a quick look at how different types of mills perform, based on a study from Kenya:

| Efficiency Type | Owner-Operated Mills | Non-Owner-Operated Mills | Reported Difference |

|-------------------------|---------------------|-------------------------|---------------------------------------------|

| Overall Technical Efficiency | No significant difference | No significant difference | Both groups show similar overall technical efficiency |

| Managerial Efficiency | Slightly less efficient (inefficiency ~27.6%) | Slightly more efficient (inefficiency ~26.9%) | No statistically significant difference between groups |

| Organisational Efficiency| Efficiency score ~0.893 (inefficiency ~11%) | Efficiency score ~0.957 (inefficiency ~4%) | Non-owner-operated mills significantly more efficient |

You can see that technical and managerial efficiency stay about the same, but non-owner-operated mills have better organizational efficiency. If you want to boost productivity, consider learning from these models or hiring skilled help.

Remember: Take your time to compare key features and read the manual. The right small scale rice milling machine will make your rice milling journey smooth and rewarding.

Preparing for Rice Milling

Getting ready to use your rice milling machine is just as important as the milling itself. When you set up your workspace, clean your paddy, and check your machine, you set yourself up for success. Let’s walk through each step so you can start strong.

Workspace Setup

First, pick a spot that’s clean, dry, and well-ventilated. You want enough space to move around and handle your equipment safely. Place your machine on a sturdy, flat surface. This helps prevent shaking or tipping during operation.

Here’s a quick checklist for your workspace:

Tip: A tidy workspace keeps you safe and helps you spot problems before they start.

Pre-Cleaning the Paddy

Before you load your machine, you need to clean your paddy. This step removes stones, dirt, and other debris that can damage your machine or lower the quality of your rice. You can use a simple sieve or a winnowing basket. Some people even use a fan to blow away lighter particles.

Follow these steps for pre-cleaning:

Pour your paddy into a large tray or basket.

Shake or stir to let small stones and dirt fall to the bottom.

Remove any visible debris by hand.

Use a fan or gentle breeze to blow away husks and dust.

Note: Clean paddy means better rice and fewer machine problems.

Machine Inspection

Now, check your rice milling machine before you turn it on. Look for loose bolts, worn belts, or any leftover grains from the last use. Make sure all parts are dry and free from rust. If your machine has a manual, keep it handy for quick reference.

Here’s a simple inspection table:

| Part to Check | What to Look For | Action Needed |

|--------------------|---------------------------|----------------------|

| Hopper | Leftover grains, dust | Clean out |

| Belts and Pulleys | Wear, looseness | Tighten or replace |

| Blades/Drums | Rust, stuck grains | Wipe and clean |

| Electrical Cord | Frays, damage | Replace if needed |

Always unplug your machine before you inspect or clean it.

When you follow these steps, you protect your equipment and get the best rice possible. A little preparation goes a long way!

Operating Steps for a Small Scale Rice Milling Machine

Loading the Rice

You have your workspace ready and your paddy cleaned. Now it’s time to load the rice into your rice milling machine. This step might seem simple, but it sets the tone for the whole milling process. If you rush or overload the hopper, you can cause jams or uneven polishing. Always check the machine’s manual for the recommended amount of rice per batch.

Here’s how you can load the rice the right way:

Measure the amount of rice you want to mill. Use a scoop or container that matches your machine’s capacity.

Pour the rice slowly into the hopper. Spread it out so it doesn’t pile up in one spot.

Watch for any foreign objects or clumps. Remove them before they go into the machine.

Make sure the hopper lid is closed if your model has one.

Tip: Never fill the hopper above the maximum line. Overloading can damage the machine and affect the polishing quality.

Adjusting Settings

Before you start operating a rice milling machine, you need to set it up for the best results. Most machines let you adjust the pressure, speed, and sometimes the polishing level. These settings control how much bran gets removed and how shiny your milled rice will look.

Here’s a quick guide to adjusting your settings:

| Setting | What It Affects | When to Adjust |

|-----------------|------------------------|--------------------------|

| Pressure | Bran removal, breakage | If you see too many broken grains or leftover bran |

| Speed | Polishing evenness | If rice looks uneven or takes too long |

| Polishing Level | Shine and appearance | If you want extra glossy rice |

Note: Start with the basic steps and default settings if you’re new to milling. You can fine-tune as you get more comfortable with the machine.

Starting the Machine

Now you’re ready to begin operating a rice milling machine. Safety comes first, so double-check that everything is in place. Make sure the machine is plugged in and all covers are secure. Stand clear of moving parts before you hit the power switch.

Follow these steps to start the milling process:

Turn on the main power switch.

Listen for any strange noises. If you hear grinding or rattling, turn off the machine and check for blockages.

Watch as the rice moves through the machine. You should see the grains pass from the hopper into the huller, then into the polishing section.

If your machine has a window or clear panel, keep an eye on the rice as it goes through polishing. This helps you spot any problems early.

Safety Alert: Never reach into the machine while it’s running. Always turn off the power before making adjustments or clearing jams.

Starting the machine marks the real beginning of your rice milling journey. With careful loading, smart settings, and safe operation, you’ll get high-quality milled rice every time. As you practice, you’ll learn how small changes in pressure or speed can make a big difference in the final polishing and rice quality.

Monitoring the Process

Once you start operating a rice milling machine, you need to keep a close eye on every step. Good monitoring helps you catch problems early and keeps your rice looking its best. You want to make sure the machine runs smoothly, the grains move through each stage, and the polishing stays even.

Here’s what you should watch for during the process:

Listen for changes: The sound of the machine tells you a lot. A steady hum means things are working well. If you hear grinding, rattling, or sudden stops, turn off the machine and inspect for jams.

Tip: Use a simple control chart or notebook to track changes in polishing quality, grain breakage, and machine noise. This habit helps you spot trends and improve your results over time.

Continuous monitoring does more than just prevent mistakes. It helps you maintain stable polishing and consistent rice quality. Many operators use control charts to track variation and stability. Regular calibration of your machine ensures you get the same grain size and shine every time. Sampling and testing for moisture content and broken grains give you real-time feedback. When you keep learning and adjusting, you get better at producing beautiful, polished rice.

Collecting the Rice

When the milling and polishing finish, it’s time to collect your rice. This step might seem simple, but how you collect and handle the rice affects both yield and quality. You want to make sure you get the most out of each batch and keep your grains in top shape.

Follow these steps for efficient collection:

Place clean containers or trays under the rice outlet before you start milling.

Wait until the polishing cycle ends and the last grains exit the machine.

Gently scoop or pour the rice into storage bags or bins. Avoid rough handling, which can break the grains.

Separate the bran and broken grains if your machine has a sorting feature. This gives you a higher percentage of whole, polished rice.

The way you collect and handle your rice can boost your yield and keep your grains looking great. Here’s a table that shows how different factors affect milling recovery and rice quality:

| Factor/Procedure | Description | Effect on Milling Recovery and Rice Quality |

|----------------------------------|------------------------------------------------------------------------------------------------------|-------------------------------------------------------------------|

| Moisture content management | Harvest at 20-25%, thresh at 15-20%, mill at 14-15% moisture | Minimizes grain breakage and maximizes head rice yield |

| Machine technology | Rubber roll machines cause less damage than metal roller or Engelberg mills | Higher milling recovery and less broken rice |

| Machine operation parameters | Maintain machine level, optimize feed rate, set RPM (800-1000 for rubber rolls), adjust clearances | Proper operation reduces breakage and improves yield |

| Operator skill and maintenance | Skilled adjustments and regular cleaning maintain efficiency | Sustains high milling recovery |

| Postharvest handling | Avoid over-drying, gentle transport, proper storage | Prevents internal fractures and breakage |

| Cultivar selection | Use stress-tolerant varieties | Improves milling yield and breakage resistance |

| Harvest timing | Avoid delayed harvesting | Maintains milling recovery |

You can see that careful handling, the right machine settings, and good timing all help you get more polished rice with fewer broken grains. When you pay attention to these details, you get the best results from every batch.

Note: Always store your polished rice in a cool, dry place. Good storage keeps your rice fresh and protects the shine from the polishing process.

Rice Milling Machine Safety

Personal Safety

When you use a rice milling machine, your personal safety should always come first. You might think the process looks simple, but accidents can happen quickly if you skip basic precautions. Many injuries in rice milling come from sharp tools, moving parts, or slips in wet areas. You can avoid most of these problems by following a few simple safety guidelines.

Start by wearing the right gear. Gloves protect your hands from cuts and scrapes. Safety boots keep your feet safe from heavy objects and sharp tools. Earmuffs help protect your hearing if your machine is loud. Many people forget about these items, but they make a big difference.

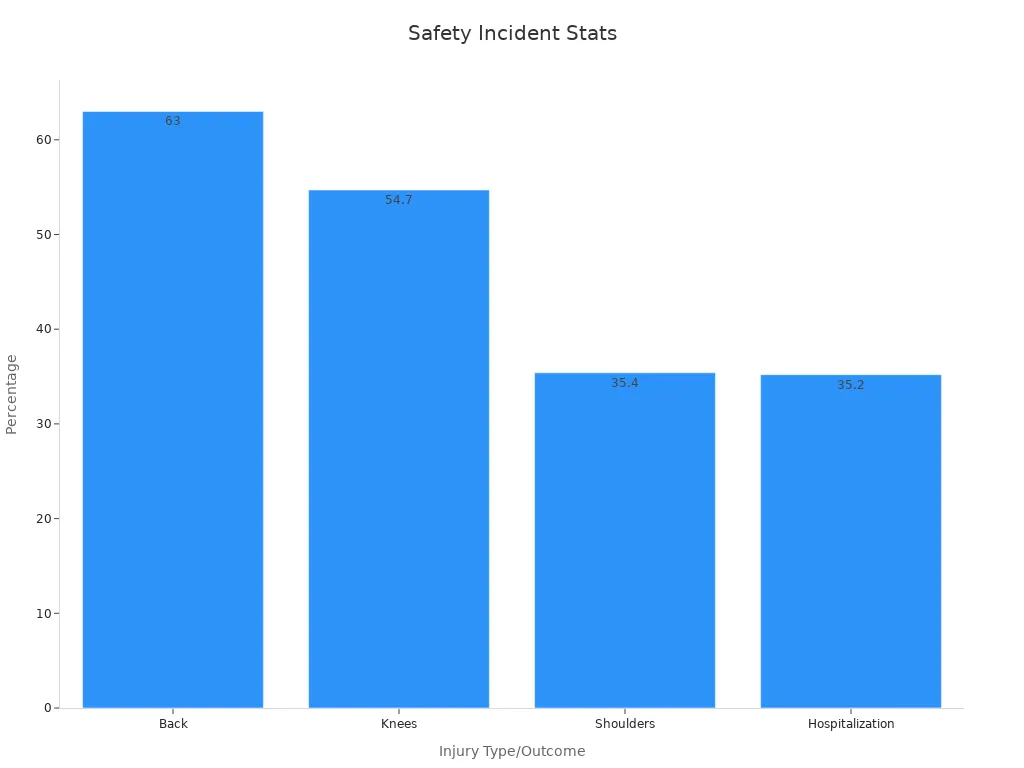

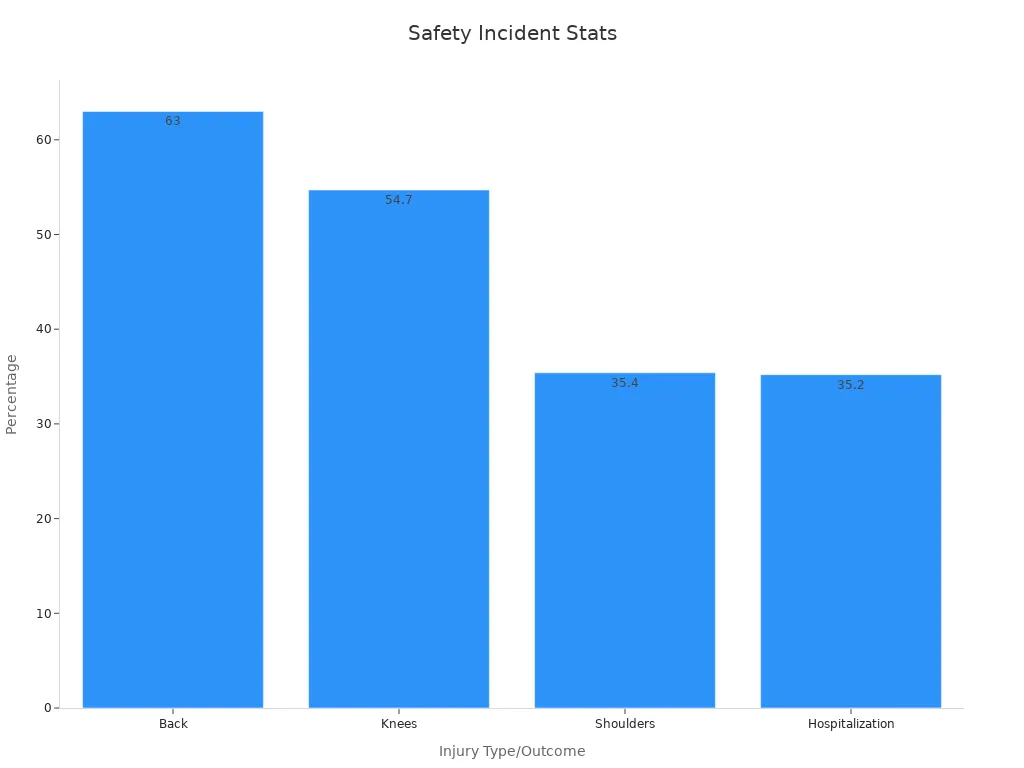

Take a look at the table below. It shows how common different injuries are for people working with rice milling machines and related equipment:

| Injury Type | Prevalence / Risk Factors | Notes |

|-------------------|-------------------------------------------------------------------------------------------|----------------------------------------------------------------------------------------|

| Back | 63% prevalence of musculoskeletal problems | Higher risk with tiller/harvester use (OR=2.8), transplantation (OR=3.6), no safe footwear (OR=2.88) |

| Knees | 54.7% prevalence | Higher risk with manual cultivation (OR=1.35), safety footwear use (OR=1.93), lower with tractor use (OR=0.53) |

| Shoulders | 35.4% prevalence | Risk higher with tiller/harvester use (OR=1.6), earmuff use (OR=2.5), increases with age (4% per year) |

| Elbows | Risk higher with transplantation (OR=4.43), earmuff use (OR=2.06), tiller use (OR=1.19), increases with age (OR=1.03) | Lower risk with double transplantation (OR=0.62) |

| Injury Timing | 37.2% injuries in spring, 73.2% during daytime | Most injuries in paddy fields (13.3%) and pesticide spraying (9.6%) |

| PPE Usage | 95.6% reported using PPE, mostly safety footwear | Limited PPE use beyond footwear |

| Hospitalization | 35.2% of injuries resulted in hospitalization | |

You can see that back and knee injuries are very common. Many people end up in the hospital because they do not take enough precautions. Most workers use safety footwear, but other protective gear is often ignored. Gloves, boots, and earmuffs are not just for show—they help you avoid serious injuries.

Here are some easy steps you can follow to stay safe:

Tip: Older adults and men face a higher risk of injury, especially when using machines or sharp tools. If you feel tired, take a break. Fatigue can lead to mistakes.

Many accidents happen because people rush or skip basic precautions. You should always follow the safety guidelines in your machine’s manual. If you are unsure about any step, ask for help or look for training. Simple habits, like wearing the right gear and keeping your workspace clean, can keep you safe every day.

Emergency Procedures

Accidents can happen fast when you use a rice milling machine. You need to know what to do if something goes wrong. Quick action can protect you and your equipment. Here’s how you can handle emergencies with confidence.

1. Power Failure or Electrical Shock

If the power suddenly goes out or you suspect an electrical shock, stay calm. Turn off the machine right away. Unplug it from the wall. Never touch any exposed wires or try to fix electrical parts yourself. Call a qualified electrician if you see sparks or smell burning.

⚡ Tip: Always keep your hands dry when handling plugs or switches. Wet hands increase the risk of shock.

2. Machine Jams or Blockages

Sometimes, rice or debris can jam the machine. If you hear strange noises or the machine stops, turn off the power immediately. Wait for all moving parts to stop. Never reach inside while the machine is running. Use a wooden stick or tool to clear blockages. Check the manual for safe ways to open and clean the machine.

3. Fire or Smoke

If you see smoke or fire, act fast. Turn off the power and unplug the machine. Use a dry powder fire extinguisher if you have one nearby. Never use water on electrical fires. Move away from the area and call emergency services if the fire spreads.

| Emergency Type | What To Do First | Who To Call |

|---------------------|---------------------------------|-----------------------|

| Power Failure | Turn off and unplug machine | Electrician |

| Jam/Blockage | Power off, clear with tool | Technician (if needed)|

| Fire/Smoke | Unplug, use extinguisher, evacuate| Fire Department |

| Injury | Stop machine, give first aid | Medical Help |

4. Personal Injury

If you or someone else gets hurt, stop the machine right away. Give first aid if you know how. For cuts or scrapes, wash the area and cover it with a clean bandage. For serious injuries, call for medical help. Keep a first aid kit close to your workspace.

Note: Practice emergency drills with your family or coworkers. Knowing what to do makes everyone safer.

5. Emergency Shutdown

Every rice milling machine has a main power switch. Learn where it is before you start. In any emergency, use this switch to shut down the machine quickly. Teach others in your home or shop how to use it too.

You can’t predict every problem, but you can prepare. Review these steps often. Keep emergency numbers posted near your workspace. When you focus on safety, you protect yourself and your rice milling machine.

Troubleshooting Rice Milling Machines

Uneven Milling

You might notice that your rice comes out with different colors or textures. Some grains look polished, while others still have bits of bran. This problem is called uneven milling. It can be frustrating, but you can fix it with a few simple checks.

Uneven milling often happens when your machine settings are off or the parts inside are not working together smoothly. Sometimes, the rice grains do not move evenly through the milling chamber. This can happen if you overload the hopper or if the feed gate is not set right. Even small changes in how you load the rice or adjust the settings can make a big difference.

Tip: Always start with a small batch when you try new settings. This helps you spot problems before you waste a lot of rice.

Here are some common reasons for uneven milling and what you can do:

Researchers have found that changes in the way rice grains move inside the milling chamber can change how much energy is used and how well the grains get polished. When you keep the flow of rice grains steady and adjust the settings based on your machine’s size, you get more even results. Scientists use special computer models to study how rice grains interact inside the machine. These studies show that the right settings for feed gate weight and milling time help you get better head rice yield and more uniform polishing.

Here’s a quick checklist to help you troubleshoot uneven milling:

| Problem | What to Check | What to Do |

|--------------------------|------------------------------|------------------------------|

| Some grains not polished | Pressure/speed too low | Increase pressure/speed |

| Too many broken grains | Pressure/speed too high | Lower pressure/speed |

| Mixed results in one batch| Overloading or poor calibration | Reduce load, recalibrate |

| Output changes each time | Dirty or worn parts | Clean or replace parts |

If you keep seeing uneven milling, try adjusting one setting at a time. Write down what you change and what happens. This way, you can find the best setup for your rice milling machines and get the most out of every batch.

Remember: Consistent milling comes from careful adjustments and regular cleaning. Take your time, and you will see better results.

Excessive Noise

Does your rice milling machine sound louder than usual? Excessive noise can be annoying, but it also signals that something needs your attention. You want your machine to run smoothly and quietly. When you hear grinding, rattling, or banging, it’s time to check things out.

Common Causes of Excessive Noise

You might hear extra noise for several reasons. Here are some of the most common:

Tip: Always turn off and unplug your machine before you inspect or fix anything. Safety comes first!

How to Diagnose the Noise

You can use your ears and eyes to find the source of the noise. Try these steps:

Listen closely to where the noise comes from. Is it near the hopper, the motor, or the outlet?

Look for loose bolts or covers. Tighten them with a wrench or screwdriver.

Spin the rollers or drums by hand (with the machine off). Do they move smoothly, or do you feel resistance?

Check for debris inside the machine. Remove any stones, metal, or leftover grains.

Inspect the bearings. If you see rust or feel roughness, you may need to replace them.

Add oil or grease to moving parts if they look dry.

Quick Troubleshooting Table

| Noise Type | Likely Cause | What You Should Do |

|--------------------|---------------------|------------------------------|

| Grinding | Foreign object | Remove debris |

| Rattling | Loose parts | Tighten bolts and covers |

| Squeaking | Dry parts | Lubricate moving parts |

| Banging | Misaligned rollers | Realign or adjust rollers |

| Humming | Worn bearings | Replace bearings |

Note: If the noise continues after you check these things, call a technician. Sometimes, machines need professional repair.

You want your rice milling machine to last a long time. Regular cleaning and maintenance help prevent noise problems. Listen to your machine every time you use it. When you catch strange sounds early, you save time and money. Quiet machines mean better rice and a safer workspace!

Cleaning and Maintenance

Daily Cleaning

You want your rice milling machine to keep working smoothly and give you the best polishing results every time. Daily cleaning is the first step. Dust, bran, and leftover grains can build up fast, especially after a busy day of milling and polishing. If you skip this step, your machine might get clogged or start working less efficiently.

Start by unplugging your machine. Use a soft brush or cloth to wipe down the outside and inside surfaces. Pay close attention to the hopper, polishing chamber, and any trays or bins that collect rice or bran. Remove any visible debris. If your model has removable parts, take them out and clean them with warm water. Dry everything well before putting it back.

Daily cleaning and quick inspections help you spot small problems before they turn into big ones. This routine keeps your machine running at its best and supports a safe, hygienic workspace. Many experts say that daily cleaning routines are a key part of regular maintenance tasks. They help prevent dust and debris from causing breakdowns or lowering the quality of your polishing.

Tip: Make daily cleaning a habit. It only takes a few minutes, but it can save you hours of trouble later.

Deep Cleaning

Sometimes, your machine needs more than just a quick wipe. Deep cleaning goes further. You should do this every week or after heavy use. Deep cleaning helps remove stubborn buildup from the polishing rollers, huller, and separator. It also keeps your machine looking and working like new.

Here’s a simple deep cleaning checklist:

Unplug the machine and let it cool down.

Disassemble the main parts, like the polishing chamber, huller, and separator.

Soak removable parts in warm, soapy water to loosen stuck-on bran and polishing residue.

Use a soft brush to scrub away any buildup, especially in the polishing area.

Rinse and dry all parts completely.

Wipe down the motor housing and any non-removable surfaces.

Reassemble the machine and check for loose screws or worn parts.

Deep cleaning does more than just improve polishing results. Studies show that regular cleaning, following the manufacturer’s schedule, prevents blockages and wear. It also helps you catch small issues early, so you can fix them before they become expensive repairs. Keeping your machine clean reduces friction and wear, which means your polishing stays consistent and your equipment lasts longer.

Note: Deep cleaning is a great time to check for any signs of damage or wear. Replace worn polishing rollers or seals right away.

Lubrication

Lubrication is another important part of maintenance. Moving parts like bearings, rollers, and gears need oil or grease to work smoothly. If you forget this step, your machine might get noisy or even break down. Good lubrication keeps the polishing action smooth and quiet.

Check your manual to see which parts need oil and how often. Usually, you should add a few drops of oil to the bearings and other moving parts after every deep cleaning. Wipe away any old grease or dirt before adding new lubricant. This helps prevent buildup that can slow down the polishing process.

A well-lubricated machine uses less energy and gives you better polishing results. It also helps your equipment last longer. Make lubrication part of your regular maintenance tasks, and you’ll notice the difference in both performance and rice quality.

Reminder: Always use the type of oil or grease recommended by your machine’s manufacturer. The wrong lubricant can damage the polishing parts.

Storage

Storing your rice milling machine the right way helps you keep it running smoothly for years. You might think storage is simple, but a few smart steps can make a big difference. Let’s walk through what you need to do after cleaning and lubricating your machine.

First, always choose a dry and cool place for storage. Moisture is the enemy of metal parts. If you leave your machine in a damp spot, you risk rust and mold. Find a spot away from direct sunlight and water sources. A corner in your kitchen, pantry, or a clean shed works well.

Before you put your machine away, double-check that every part is dry. Wipe down all surfaces with a soft cloth. If you see any leftover water, dry it off right away. Even a little moisture can cause trouble over time.

You should also cover your machine. A simple cloth or plastic cover keeps out dust and insects. If your machine came with a custom cover, use it. This small step protects the moving parts and keeps your machine looking new.

Here’s a handy checklist for storing your rice milling machine:

Tip: If you live in a humid area, place a small packet of silica gel or a moisture absorber near your machine. This helps keep the air dry and protects against rust.

You might want to check on your machine every few weeks, especially if you don’t use it often. Look for signs of rust, dust, or insect activity. If you spot any problems, clean and oil the machine again before your next use.

Here’s a quick table to help you remember the best storage conditions:

| Storage Factor | Why It Matters | What To Do |

|---------------------|------------------------------|-----------------------------------|

| Dry Environment | Prevents rust and mold | Store away from water sources |

| Cleanliness | Keeps machine ready to use | Wipe and cover after cleaning |

| Stable Surface | Avoids damage or tipping | Use a flat, sturdy shelf or table |

| Covered Machine | Blocks dust and insects | Use a cloth or plastic cover |

Taking care of storage means you spend less time fixing problems and more time milling great rice. Treat your machine well, and it will reward you with years of reliable service.

Efficiency Tips for Rice Milling

Maximizing Yield

You want to get the most rice out of every batch of paddy. Maximizing yield means you waste less and earn more. The best way to do this is by paying attention to your rice polishing process and keeping your equipment in top shape. When you use the right features on your machine, you can boost your yield and improve your efficiency.

Take a look at this table. It shows how different key performance indicators (KPIs) affect your rice milling results:

| KPI Name | Industry Benchmark | What It Means for You |

|-------------------------|--------------------|--------------------------------------------------------------------|

| Production Yield | 68-72% | Shows how much polished rice you get from raw paddy |

| Milling Yield Percentage| 70-72% | Measures how well you turn raw rice into milled rice |

| Equipment Downtime | Below 10% | Less downtime means more rice polishing and higher efficiency |

If you keep your equipment downtime low and focus on the polishing process, you can reach or even beat these benchmarks. Many rice millers upgrade their machines and train their staff to get better results. These changes help you process rice faster, save money, and stay ahead of the competition. When you maximize yield, you see a direct boost in your efficiency and profit.

Tip: Regularly check your machine’s features and settings. Small tweaks can make a big difference in your rice polishing results.

Reducing Broken Grains

Broken grains can lower the quality of your milled rice and hurt your profits. You want as many whole grains as possible after polishing. The way you handle your rice and adjust your machine’s features plays a big role here.

Try these steps to reduce broken grains:

When you pay attention to these details, you protect the quality of your rice. Modern machines often come with features that let you fine-tune the polishing process. This helps you get more whole grains and less waste. Remember, gentle handling and careful polishing lead to better results.

Note: Even small changes in your polishing settings can improve the quality of your rice and reduce breakage.

Consistent Results

Consistency is key if you want high-quality rice every time. You need to keep your polishing process steady and repeatable. Start by using the same settings for each batch. Track your results in a notebook or on your phone. If you notice changes in the quality or shine of your rice, adjust your features as needed.

Here are some ways to keep your polishing results consistent:

Modern rice milling machines make it easier to get consistent results. They come with features that help you control every step of the polishing process. When you focus on consistency, you build a reputation for quality and reliability.

Remember: Consistent polishing means your customers trust your rice. Good habits and regular checks keep your efficiency high and your rice looking great.

Learning Resources

Learning how to use your small scale rice milling machine does not stop after your first batch. You can always find new tips, tricks, and solutions. Let’s look at some of the best places to learn more and get help when you need it.

Manuals and Guides

Start with the manual that comes with your machine. This booklet gives you step-by-step instructions for setup, operation, and maintenance. You will find diagrams, safety tips, and troubleshooting charts. If you lose your manual, check the manufacturer’s website. Many companies post digital copies online.

Tip: Keep your manual in a safe spot near your machine. You will want to check it often, especially when you try new settings or run into problems.

You can also find downloadable guides and how-to articles on trusted websites. Some suppliers, like chinaricemill.com, offer video tutorials. Watching someone else use the machine can make things much clearer.

Here’s a quick list of what you might find in a good manual or guide:

Online Communities

You are not alone on your rice milling journey. Many people share your questions and experiences. Online communities give you a place to ask for help, swap stories, and learn from others.

Popular places to connect include:

Note: Always read the group rules before posting. Be polite and thank people who help you.

You might even find local groups in your area. Meeting up in person can help you see machines in action and build friendships.

Expert Advice

Sometimes, you need help from a pro. Experts can solve tough problems, teach you advanced tricks, or help you choose the right machine. You can reach out to:

Many experts offer phone support, email help, or even video calls. Some companies provide live chat on their websites. If you attend trade shows or workshops, you can meet experts face-to-face.

| Where to Find Experts | How They Help You |

|---------------------------|----------------------------------|

| Local dealers | Hands-on demos, quick repairs |

| Manufacturer hotlines | Troubleshooting, spare parts |

| Online webinars | Training, Q&A sessions |

️ Tip: Don’t wait until you have a big problem. Build a relationship with an expert early. They can save you time and money.

You have many ways to keep learning. Use your manual, join online groups, and reach out to experts. With these resources, you will become a confident rice milling machine user in no time.

You can master a small scale rice milling machine by starting with the basics and building your skills over time. Focus on safety, regular cleaning, and learning from your manual or experts. Many users see better grain recovery, less breakage, and more uniform rice. Check out these industry highlights:

| Aspect | Details |

|---|---|

| Market Size (2024) | USD 1.32 Billion |

| Key Benefits | High grain recovery, low breakage, uniform quality |

| Operational Advantages | Hygienic, efficient, easy to use |

FAQ

How much rice can I mill at once?

Most small machines handle 5–20 kg per batch. Check your manual for the exact amount. If you overload the hopper, you risk jams or uneven milling. Start with smaller batches until you get comfortable.

Do I need to soak the paddy before milling?

No, you don’t need to soak the paddy. Just make sure it’s dry and clean. Milling wet paddy can clog your machine and lower rice quality.

How often should I clean my rice milling machine?

You should clean your machine after every use. Daily cleaning keeps it running smoothly and prevents jams. Deep clean once a week or after heavy use.

What should I do if the machine jams?

Turn off and unplug the machine right away. Wait for all parts to stop moving. Use a wooden stick to clear the jam. Never reach inside while it’s running.

Can I use the machine for other grains?

Some machines can handle other grains like wheat or corn. Check your manual first. Using the wrong grain may damage the machine or reduce rice quality.

Why does my rice come out broken?

Broken grains usually mean too much pressure or speed. Try lowering the settings. Also, check for worn parts or overloading. Gentle handling helps keep grains whole.

Where can I find spare parts?

You can order spare parts from your supplier or the manufacturer’s website. Some local dealers also carry common parts. Always use genuine parts for the best results.

Is it safe for kids to help with rice milling?

Kids can help with simple tasks like cleaning paddy or collecting rice. Only adults should operate the machine. Always supervise children around moving parts.